Its a public holiday today and there is no work.

Thursday (27/5/2010)

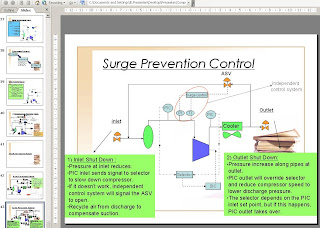

After 2 days of working on the drawing, i've finally finished the drawing. Not exactly finished, but manage to draw the diagram according to what i know and learned. Showed it to my supervisor and he said that there are many more blocks to add till its perfect. Here is the diagram, it may look simple but it took a long time to explain and to find out.

Wednesday (26/5/2010)

I continued drawing my block diagram of the compressor and turbine. Fortunately, a senior process engineer helped me out in explaining and pointing out where the blocks should be and should be connected. After that, it was a little easier to draw with the help of the Caterpillar gas turbine booklet. Here is the sketch of the diagram:

Tuesday (25/5/2010)

Today, the clients from Shell Sarawak came in. This means my supervisor was busy attending to them. I just continues learning and reading about turbine and compressors. I tried drawing out the connection but it would't make sense. Later in the evening, my supervisor handed me a handbook from Caterpillar about gas turbines.

Monday (24/5/2010)

Finally, i'm done with my presentation. I handed it over to my supervisor and he said it was ok but there is still room to improve. Later, i was given a task to draw a block diagram of a turbine and compressor. Here are some pictures of the slides: